Heat Flow Redefined: Thermal Interface Material Market Powers to USD 8.9 billion by 2035

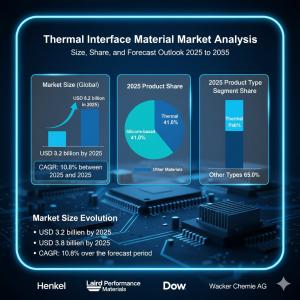

Electronics miniaturization and EV proliferation ignite a USD 3.2 billion market at 10.8% CAGR, silicone-based materials at 41%, thermal pads at 35%

NEWARK, DE, UNITED STATES, November 6, 2025 /EINPresswire.com/ -- The thermal interface material market begins at USD 3.2 billion in 2025 and surges to USD 8.9 billion by 2035. It advances at a 10.8% CAGR. Electronics miniaturization demands superior heat dissipation in compact designs.

C-suite leaders prioritize thermal reliability for device longevity. Sales teams chase velocity in high-margin segments. Product managers balance conductivity with application ease. R&D pushes boundaries on nano-enhanced formulas.

Fast facts:

* Market size now: USD 3.2 billion

* Market size 2035: USD 8.9 billion

* CAGR: 10.8%

* Top product segment: Thermal pads (35%)

* Form leader: Data not disclosed in client file

* Source leader: Data not disclosed in client file

* Growth hubs: Asia Pacific, North America, Western Europe

Review the full report to examine in-depth market dynamics, strategic developments, and growth opportunities across key regions! Request Sample Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-15462

Manufacturers select materials for consistent thermal performance. They favor solutions that integrate seamlessly into automated lines.

- Thermal pads win for fastest growth via easy application in electronics cooling.

- Silicone-based materials lead with stability and conductivity in diverse environments.

- Electronics & semiconductors dominate through miniaturization and heat density needs.

Channels center on electronics supply chains and automotive Tier 1 partnerships. Direct integration accelerates adoption in manufacturing.

- China (11.3% CAGR): Electronics scale drives massive integration.

- India (10.7% CAGR): Automotive electrification demands cost-effective solutions.

- United States (8.6% CAGR): Premium adoption in data centers.

- Germany (9.1% CAGR): Industrial automation requires precision.

- Japan (7.4% CAGR): Semiconductor precision mandates reliability.

R&D:

- Develop nano-enhanced silicone targeting 15 W/mK.

- Test phase-change prototypes in EV battery simulations.

- Validate graphene integration for conductivity gains.

Marketing & Sales:

- Bundle thermal pads with application guides for EMS.

- Demo automated dispensing at trade shows.

- Offer volume discounts on high-conductivity lines.

Regulatory & QA:

- Certify materials to automotive standards.

- Implement void detection in pad production.

- Update documentation for new formulations.

Sourcing:

- Secure dual suppliers for silicone resins.

- Build inventory in key manufacturing hubs.

- Negotiate contracts for stable pricing.

- Test competitor pads in thermal shock cycles.

- Launch EV-focused gap filler trials.

- Audit supply chain for material consistency.

Thermal trust builds repeat orders. Reliable heat management secures margins in weekly procurement. Act decisively to lead the interface revolution.

Acquire the complete report to access detailed projections, country-level insights, company share assessments, and technology outlooks! Buy Full Report: https://www.futuremarketinsights.com/checkout/15462

Strategic Depth: Navigating the Thermal Decade

The market splits into two phases. From 2025 to 2030, value adds USD 1.9 billion or 34% of growth. Premium materials gain traction as device density rises.

From 2030 to 2035, another USD 3.8 billion flows in, claiming 66%. Mass penetration occurs in EVs and 5G. Compatibility with existing lines becomes table stakes.

Silicone-based materials hold 41% through proven reliability. They enable 98% thermal efficiency in CPUs and modules. Automated dispensing boosts line efficiency.

Epoxy-based variants secure 25% with bonding strength. They suit power electronics needing structural support. Polyimide takes 18% in high-temperature aerospace.

Thermal pads claim 35% and grow fastest. Consumer devices and semiconductors demand quick installs. Gap fillers follow at 22% in automotive.

Electronics & semiconductors generate 38%. Miniaturization packs heat into smaller spaces. Traditional cooling fails here.

EV battery management accelerates demand. Packs require materials for safety and range. 5G stations need high loads handled reliably.

Graphene integration trends upward. It promises breakthrough conductivity. Phase change materials adapt dynamically.

Costs restrain premium uptake. Consumer segments push back on prices. Application errors cut efficiency if expertise lacks.

Exploring Insights Across Emerging Global Markets:

Anti-reflective Coatings Market Share Analysis: https://www.futuremarketinsights.com/reports/anti-reflective-coatings-market-share-analysis

Inorganic Scintillators Market Share Analysis: https://www.futuremarketinsights.com/reports/inorganic-scintillators-market-share-analysis

Polyamide Market Share Analysis: https://www.futuremarketinsights.com/reports/polyamide-market-share-analysis

Flurosilicic Acid Market Share Analysis: https://www.futuremarketinsights.com/reports/flurosilicic-acid-market-share-analysis

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why Choose FMI: Empowering Decisions that Drive Real-World Outcomes: https://www.futuremarketinsights.com/why-fmi

Sudip Saha

Future Market Insights Inc.

+18455795705 ext.

email us here

Visit us on social media:

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.