Toughening Nanoparticle Additives Market Advances on Performance-Led Adoption Across High-Reliability Industries

Toughening nanoparticle additives gain traction as industries prioritize impact resistance, and lightweight performance in advanced polymers and composites.

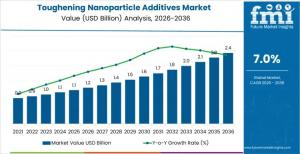

NEWARK, DE, UNITED STATES, January 19, 2026 /EINPresswire.com/ -- The global toughening nanoparticle additives market is entering a phase of sustained, performance-driven expansion as manufacturers prioritize mechanical reliability, durability, and lightweight design across advanced material systems. The market is projected to grow steadily through 2036, supported by long-term adoption in composites, structural adhesives, and engineered polymers used in automotive, aerospace, wind energy, electronics, and industrial manufacturing.

Market growth is defined less by bulk volume expansion and more by value-driven deployment in applications where fracture toughness, impact resistance, and fatigue life directly influence product lifespan and qualification outcomes. Capital investment is increasingly concentrated in nanoparticle surface treatment, dispersion technologies, and application-specific formulation support—capabilities that determine both differentiation and pricing leverage in this specialized additives segment.

Explore trends before investing – request a sample report today! https://www.futuremarketinsights.com/reports/sample/rep-gb-31476

Market Context: Why Toughening Nanoparticle Additives Matter

Toughening nanoparticle additives are engineered to enhance impact resistance and fracture toughness without compromising stiffness, thermal stability, or processability. Incorporated at low loadings, nanoparticles such as silica, core-shell elastomers, and rubber-modified systems dissipate energy and arrest crack propagation under mechanical stress. This enables material performance gains in high-stress environments while preserving part geometry and manufacturing efficiency.

Demand is anchored to end-use industries with long qualification cycles and stringent performance requirements. Automotive lightweighting initiatives, aerospace structural integrity standards, renewable energy composites, and electronics reliability targets all reinforce stable, multi-year demand. As a result, returns in this market are typically realized over extended timelines, favoring suppliers with strong materials science capabilities and disciplined capacity expansion.

Resin System and Application Structure Define Demand

The toughening nanoparticle additives market is segmented by resin system and application, reflecting how stress conditions and performance thresholds shape additive selection. Epoxy resins represent the leading resin system, accounting for 42% of market adoption. Their widespread use in structural composites and adhesives makes them a primary platform for nanoparticle-based toughening, particularly where brittleness control is critical.

By application, composites and structural adhesives dominate demand, holding 38% market share. These segments are highly sensitive to fatigue, impact, and long-term mechanical stress, making nanoparticle toughening a core formulation strategy. Additional applications include coatings and flooring, electronics encapsulation and packaging, and other high-reliability polymer systems.

Technology and Qualification Drive Adoption

Uniform dispersion is central to effective toughening. Agglomeration can negate mechanical benefits and degrade surface quality, leading buyers to prioritize suppliers offering surface-treated nanoparticles, masterbatch formats, and detailed formulation guidance. Advances in surface functionalization, reactive compatibilizers, and processing aids have improved dispersion control at micro- and nano-scales.

Processing technologies such as twin-screw extrusion, reactive extrusion, and advanced compounding systems are expanding the range of viable applications. However, qualification remains rigorous. In aerospace, automotive, and other safety-critical uses, extensive mechanical testing and validation are required before additives are embedded into approved material platforms.

Regional Growth Reflects Industrial Priorities

Growth patterns vary by country based on industrial structure and advanced materials adoption. China leads market expansion with strong demand from automotive manufacturing, electronics, industrial coatings, and wind energy composites. Domestic production capacity and improving dispersion technologies support scalable adoption.

Brazil is seeing steady growth driven by automotive components, construction materials, and industrial flooring, where durability under high temperature and humidity is essential. The United States market is shaped by aerospace, defense, electronics, and specialty composites, emphasizing consistent performance and supplier reliability over volume. Germany’s growth is tied to precision engineering, automotive systems, and industrial manufacturing, while South Korea’s adoption is driven by export-oriented electronics and automotive applications requiring high mechanical reliability.

Competitive Landscape Centers on Performance Consistency

Competition in the toughening nanoparticle additives market is defined by dispersion quality, reinforcement efficiency, and compatibility with diverse polymer matrices. Leading suppliers differentiate through engineered nanoparticle systems, tailored surface chemistries, and application-specific technical support rather than price competition alone.

Major participants include 3M Advanced Materials, Evonik Industries AG, Cabot Corporation, Arkema, BASF SE, Wacker Chemie AG, Momentive Performance Materials, Dow, Henkel, and DSM Coating Resins (Covestro). Across the market, long-term supplier relationships are built on reproducible material properties, scalable production, and the ability to support evolving formulation requirements.

Outlook: Margin-Led Growth Through Materials Science

Between 2026 and 2036, the toughening nanoparticle additives market is expected to reward companies that align advanced materials research with disciplined capacity expansion. As cost-sensitive applications remain selective, scalable production of low-dosage, high-efficiency additives will be critical. With demand anchored to durability, lightweighting, and long service life rather than short-term cycles, the market represents a steady-growth enabler within high-performance material ecosystems.

Browse Related Insights

UV-Blocking Nanoparticle Additives Market: https://www.futuremarketinsights.com/reports/uv-blocking-nanoparticle-additives-market

Additives for Metalworking Fluids Market: https://www.futuremarketinsights.com/reports/additives-for-metalworking-fluids-market

Additives for Floor Coatings Market: https://www.futuremarketinsights.com/reports/additives-for-floor-coatings-market

Sudip Saha

Future Market Insights Inc.

+18455795705 ext.

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.