Ceramic Filler Powders Market Forecast to Reach USD 4.7 Billion by 2036 as Demand Rises Across Plastics and Electronics

UK ceramic filler powders market grows at 6.2% CAGR (2026–2036), driven by construction, coatings, and advanced polymers demanding durability & quality.

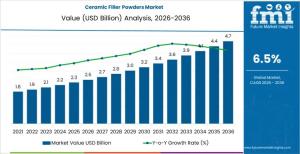

NEWARK, DE, UNITED STATES, January 19, 2026 /EINPresswire.com/ -- The global ceramic filler powders market is entering a decade of steady, performance-driven expansion, beginning at USD 2.5 billion in 2026 and projected to reach USD 4.7 billion by 2036, registering a compound annual growth rate (CAGR) of 6.50% over the forecast period. Growth is being shaped by rising use of engineered plastics, high-performance coatings, adhesives, sealants, and electronic materials that require enhanced mechanical strength, thermal stability, electrical insulation, and dimensional control.

Ceramic filler powders including alumina, silica, zirconia, and titania, are increasingly incorporated into polymer and composite systems to improve wear resistance, heat tolerance, and durability while maintaining formulation cost efficiency. The market spans major industrial regions, including Asia Pacific, Europe, North America, Latin America, and the Middle East & Africa, reflecting broad-based demand from manufacturing, infrastructure, and electronics supply chains.

Discover Market Opportunities – Get Your Sample of Our Industry Overview Today!

https://www.futuremarketinsights.com/reports/sample/rep-gb-31528

Market Context: Why Ceramic Filler Powders Are Gaining Strategic Importance

Manufacturers across automotive, industrial equipment, electronics packaging, and construction materials are turning to ceramic fillers to meet higher performance thresholds under demanding operating conditions. As automation increases and quality standards tighten, consistent, high-purity filler grades with controlled particle size distribution and reliable surface treatment are becoming essential inputs rather than optional additives.

In polymer compounds and elastomers, optimized ceramic fillers improve flow behavior, reduce shrinkage, and extend service life. In electronics and electrical applications, they support thermal management and dielectric performance, enabling component miniaturization and long-term reliability. These functional advantages are reinforcing ceramic filler powders as foundational materials across multiple value chains.

Quick Stats: Ceramic Filler Powders Market

• Market value (2026): USD 2.5 billion

• Forecast value (2036): USD 4.7 billion

• CAGR (2026–2036): 6.50%

• Leading material type: Alumina-based fillers (38% share)

• Leading application: Polymer compounds & plastics (34% share)

• Key regions: Asia Pacific, Europe, North America, Latin America, Middle East & Africa

How Material Performance Requirements Are Driving Market Growth

The primary growth driver is the need for materials that deliver mechanical reinforcement, thermal stability, and electrical insulation without compromising processability. Ceramic fillers such as alumina, silica, zirconia, and calcium carbonate are selected to improve hardness, abrasion resistance, and dimensional stability in polymers, coatings, and composites.

Purchasing decisions are heavily influenced by particle size distribution, purity, surface treatment, and compatibility with resin systems, as these factors directly affect dispersion quality and long-term performance. As applications diversify into high-performance composites, energy-efficient building materials, and advanced manufacturing systems, demand for application-specific ceramic fillers continues to rise.

Market Structure by Material Type and Application

The ceramic filler powders market is structured around performance-driven material selection and end-use requirements:

• By material type, alumina-based fillers lead adoption due to their balance of hardness, thermal resistance, and chemical stability. Other key categories include silica and silicate fillers, titania and zirconia fillers, and specialty ceramic fillers tailored for niche applications.

• By application, polymer compounds and plastics represent the largest demand segment, followed by coatings and paints, adhesives and sealants, and other uses requiring durability and dimensional control.

Alumina-based fillers account for 38% of market share, supported by established supply chains, consistent processing behavior, and broad compatibility with thermoplastics and thermosets. Polymer compounds and plastics hold a 34% share, driven by high-volume automotive, electrical, and industrial plastic production.

Regional and Country-Level Growth Dynamics

Growth varies by country based on industrial output, construction activity, and adoption of advanced material systems:

• China leads with a 7.7% CAGR, supported by large-scale construction, plastics compounding, coatings, and electronics manufacturing. Cost efficiency, supply reliability, and batch consistency are key procurement factors.

• Brazil follows at 7.3% CAGR, driven by infrastructure development, residential construction, and mineral-filled polymer systems.

• United Kingdom grows at 6.2% CAGR, emphasizing specialty coatings, insulation materials, and quality-controlled polymer applications.

• Germany records 6.1% CAGR, reflecting demand for precision-engineered plastics and coatings in automotive and industrial manufacturing.

• South Korea expands at 5.7% CAGR, led by electronics, thermal management materials, and advanced polymer formulations.

Competitive Landscape: How Suppliers Are Positioning

Competition in the ceramic filler powders market is defined by particle engineering, performance consistency, and formulation support rather than pricing alone. Leading companies such as 3M, Saint-Gobain, Henkel, Momentive, Showa Denko Materials, Imerys, CeramTec, H.C. Starck (MHC Group), Sumitomo Chemical, and Mitsubishi Chemical Group compete through engineered particle size distributions, application-specific surface treatments, and reliable global supply.

As end users demand verified performance gains and predictable processing behavior, suppliers with advanced processing capabilities and technical collaboration are strengthening their market position.

Outlook: A Performance-Driven Decade Ahead

From 2026 to 2036, the ceramic filler powders market is expected to expand steadily as industries prioritize durability, thermal performance, and material reliability. While processing complexity and cost pressures remain constraints in some segments, ongoing application diversification and rising quality standards continue to support long-term demand, positioning ceramic filler powders as essential materials in next-generation industrial formulations.

Why FMI: https://www.futuremarketinsights.com/why-fmi

Related Reports Insights from Future Market Insights (FMI)

Climate-Adaptive Wheat Fungicides Market https://www.futuremarketinsights.com/reports/climate-adaptive-wheat-fungicides-market

Demand for Benzyl Trimethyl Ammonium Chloride in Japan https://www.futuremarketinsights.com/reports/japan-benzyl-trimethyl-ammonium-chloride-market

Bt-Corn Pest Management Insecticides Market https://www.futuremarketinsights.com/reports/bt-corn-pest-management-insecticides-market

Seismic-Resistant Self-Healing Concrete Additives Market https://www.futuremarketinsights.com/reports/seismic-resistant-self-healing-concrete-additives-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.